A loadcell transmitter is used to convert loadcell outputs into a standard instrumentation analog signal such as 4-20mA or 0-10volts, it will also supply power to excite one or more loadcells. The 6004MF has many additional features such as displays for mass and programming, digital communications for direct connection to control computers and alarms. Our weighing electronics has always incorporated a precalibrate, zero trim and span trim feature. This is a simple way to set up a strain-gauge loadcell system. All the variables, such as sensitivity and range, are inserted in the precalibrate section so that the system is reasonably accurate before adding test weights. The weighing system is then zero trimmed (backbalanced) to offset the dead weight of weighbin, weighframe or weighbridge deck. With known test weights the system can be span trimmed to get higher accuracy. In some instances, such as very large weightanks where it is not possible to use test weights, precalibration using factory test certificates for loadcell sensitivity results in an acceptable overall system accuracy.

The ARM processor used incorporates a USB port and a real time clock with day/date. We have made full use of these facilities and added an optional, factory fitted, global positioning system (GPS) to cater for such applications as on-board truck weighing, positioning and data logging. In refuse removal some countries are introducing legistration for customers to pay by weight for this service. Farmers are starting to monitor crop production and fertiliser distribution by location to improve farming efficiency. Logging contractors need to load for maximum profit without incurring overweight fines.

How it works

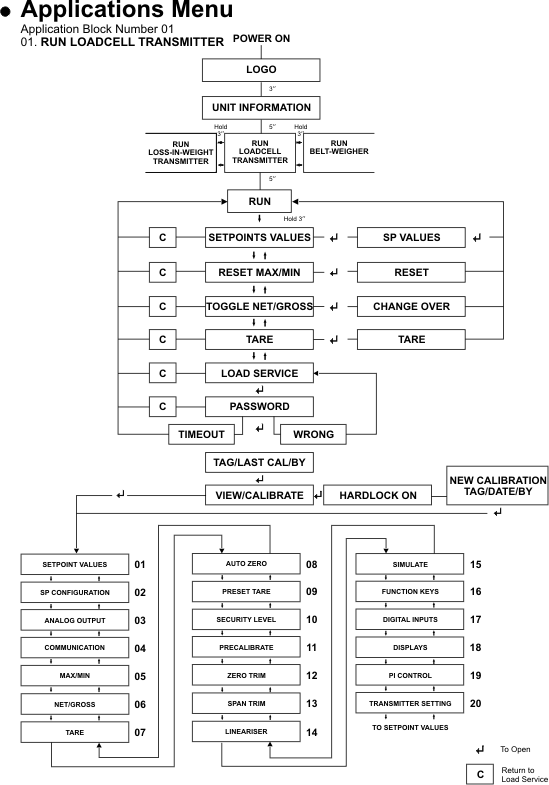

Select RUN LOADCELL TRANSMITTER if not already in this application. Press side arrow after power up when RUN (application) is displayed, key in password, enter and use side arrows to select, then enter again.

For quicker commissioning first select Security Level 1 and connect the Hardlock link. Going in to the Service menu select Calibrate, not view, in order to change settings. Change Security levels and passwords last. Note that you make changes to the whole Service menu block then press Enter.

It is advisable to first set up the Displays, Digital inputs and Function keys, then go to Precalibrate and set up loadcell values and scales. After this you can go through the Service menu blocks to select and set other functions that you require. Descriptions of these are listed in the Service menu pages.

Final calibration trim can be carried out on the system using Zero Trim and, if test weights are available, Span trim.

The Loadcell Transmitter Service menu contains the following functions:- (Detailed descriptions are listed in the Service menu section of this manual)

- Setpoint values Set values for setpoints 1-6

- Setpoint configuration Select functions for setpoints 1-6

- Analog output Select output 1-5V, 0-10V, 0-20mA or 4-20mA

- Communications Select and set up serial output

- Min/Max Select minimum and/or maximum hold

- Net/Gross Select Gross only, Net only or Net/Gross

- Tare Select Tare to zero in Net reading

- Auto zero Select and set up Auto Zero Maintenance (AZM)

- Preset tare Select Preset tare function

- Security level Select access to Operator and/or Service menu

- Precalibrate Set loadcell values, excitation, range, damping

- Zero trim Trim off empty weighbin/ weighbridge deck...

- Span trim Trim range using test weights

- Lineariser Select up to 15 points of linearising

- Simulate For testing, force analog and relay outputs

- Function keys Set functions for keys F1-4

- Digital inputs Set functions for inputs D1-6

- Displays Set main display and up to 4 auxiliary on LCD

- PI Control Change transmitter into controller

- Transmitter settings Set password, calibration, hardware & time/date